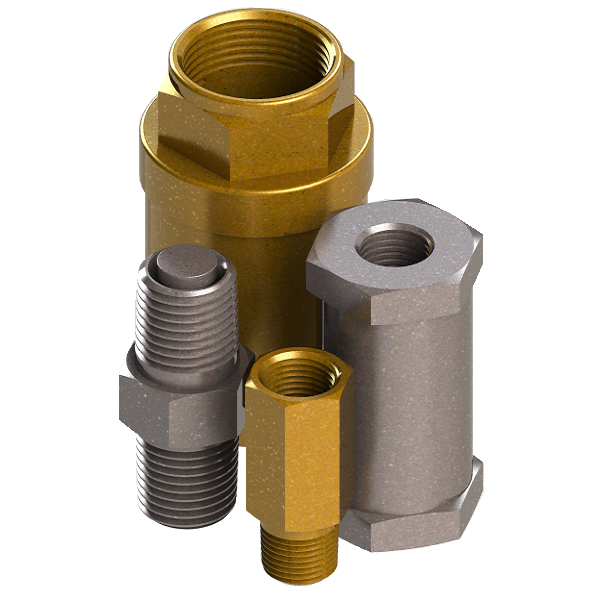

Your Specific Application, Our Custom Check Valves

When it comes to fluid control, custom check valves can be the key to optimizing performance in specialized applications. Whether you’re in industrial processing, plumbing, HVAC, or another sector, having a check valve tailored to your system’s requirements ensures efficiency, longevity, and reliability.

Why Choose Valve Check?

At Valve Check, we specialize in designing and manufacturing high-quality custom check valves that meet ANSI, NSF, and other industry standards. Our team works closely with engineers to develop solutions tailored to your system’s needs.

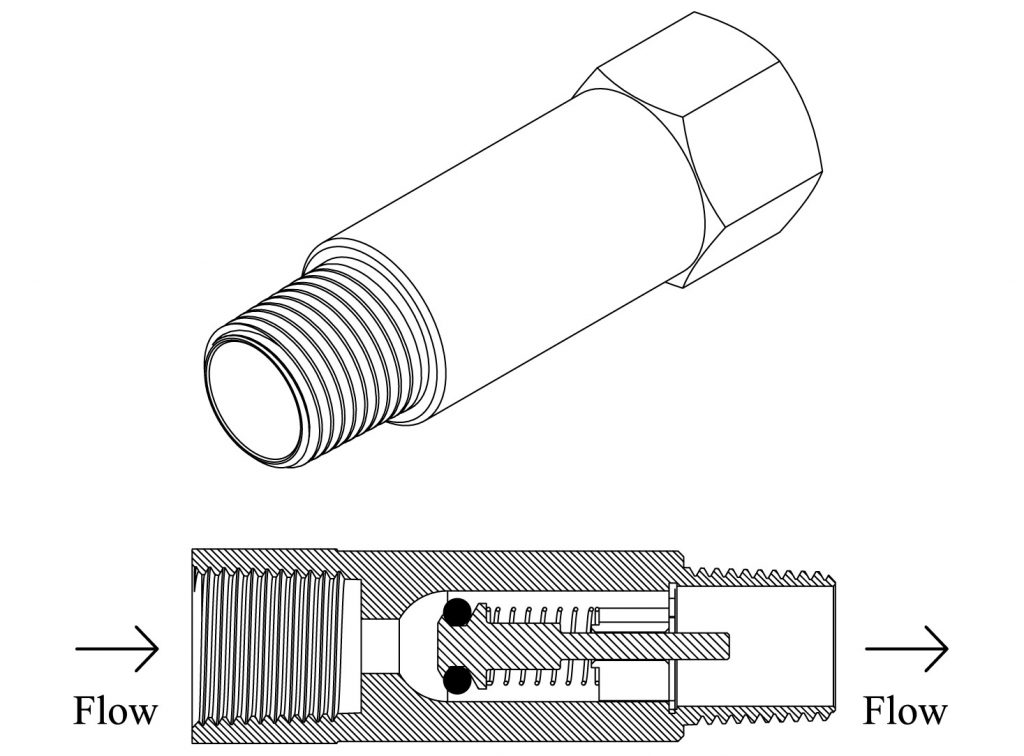

What are Custom Check Valves?

A custom check valve is a one-way valve designed and manufactured to meet specific flow, pressure, and material requirements. Unlike off-the-shelf options, these valves are engineered to accommodate unique environmental conditions, media types, and operating pressures.

Benefits of Our Customization Options

Optimized Performance – Designed to match precise flow characteristics, reducing turbulence and energy loss.

Material Selection – Available in materials like brass, stainless steel, and specialized coatings to handle corrosive or high-temperature environments.

Cracking Pressure Customization – Ensures the valve opens at the exact pressure needed for your application.

Size Arrangements – Choose between different sizes and connection types with threads that hold to NPT or SAE standards.

Extended Durability – Built to withstand the specific demands of your system, reducing maintenance and replacement costs.

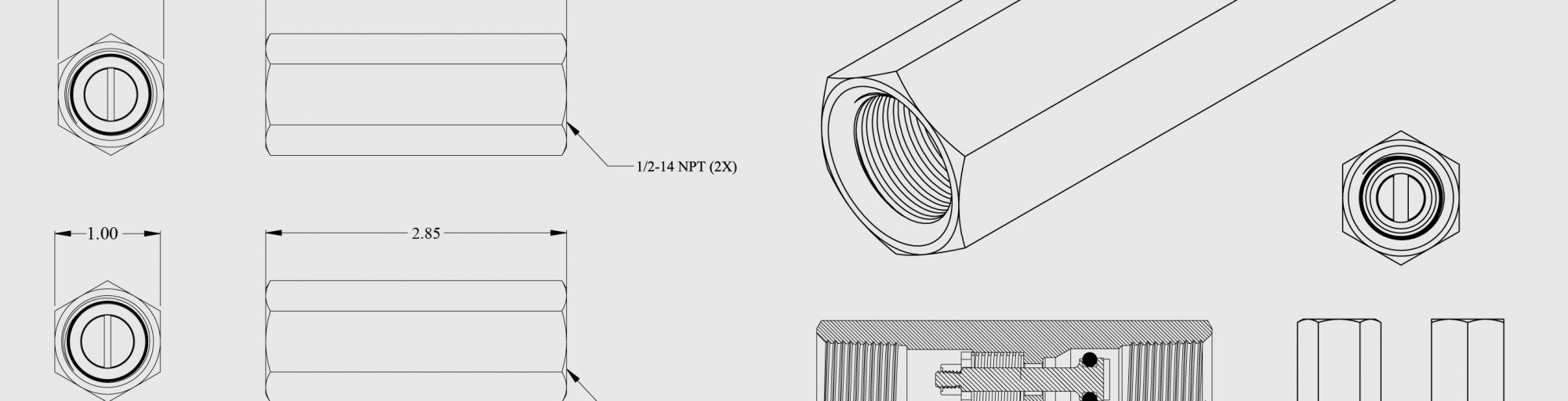

Our Check Valve Size Arrangements

Choose between different sizes and connection types with threads that hold to NPT standards.

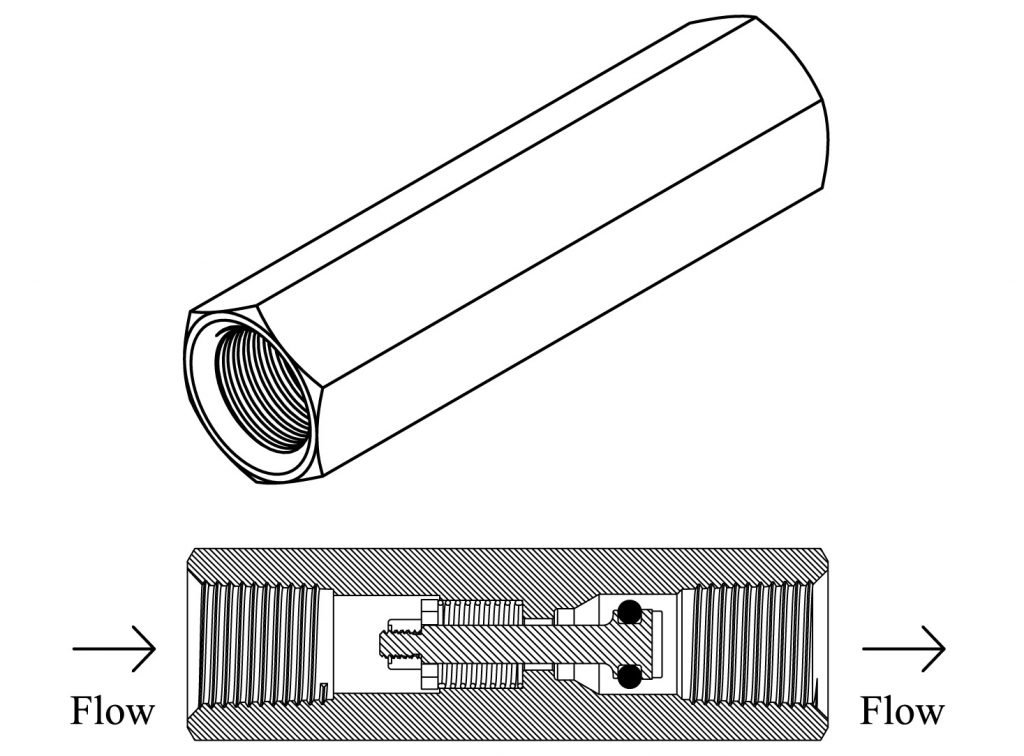

Female x Female (PP)

Ideal for joining two male-threaded pipes or fittings, providing a leak-proof seal in fluid control systems.

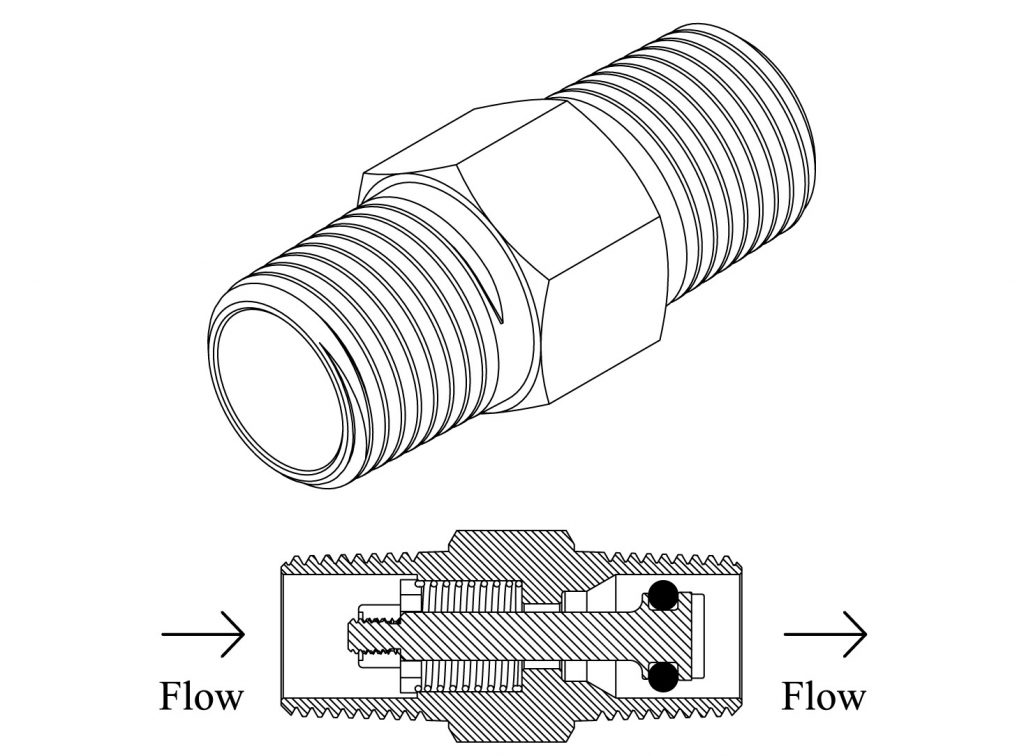

Male x Male (MM)

Designed for secure connections between two female-threaded components, ensuring a seamless fit in high-pressure applications.

Male x Female (MP)

Offers versatile connectivity between male and female-threaded components, making it a flexible option for various installations.

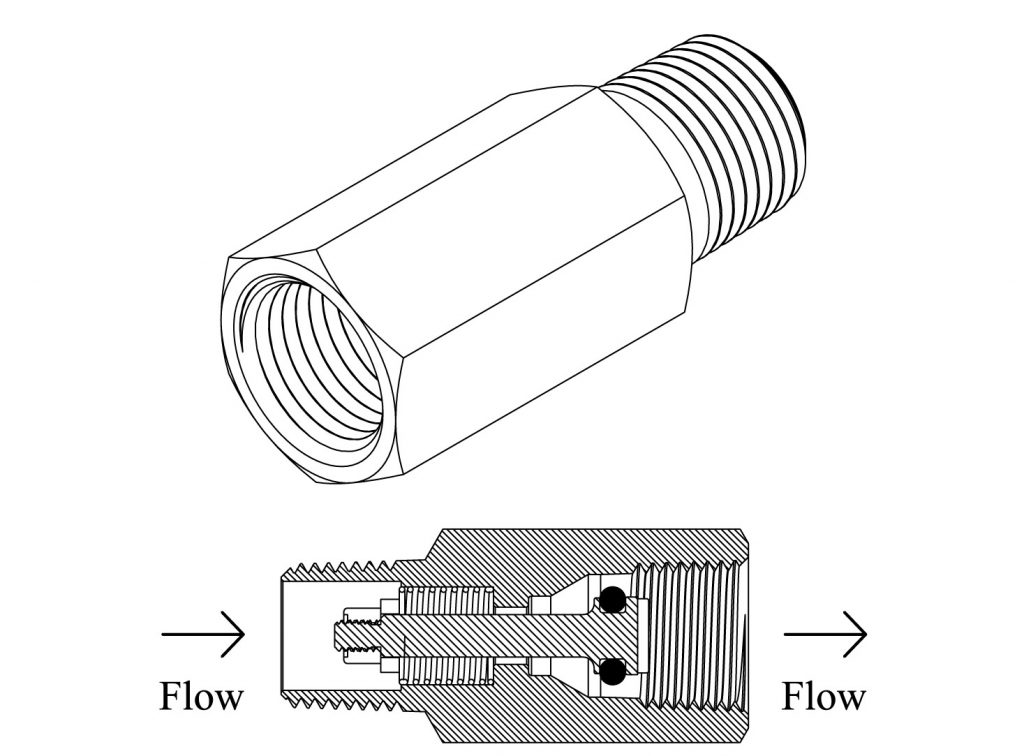

Female x Male (PM)

Allows easy adaptation between different thread types, enhancing compatibility across different piping configurations.

Request a quote

Find Your Custom Check Valves Today!

If you need a custom check valve for your next project, contact us today for a consultation. Our experts will help you select the right materials, configurations, and performance features to ensure a reliable, efficient solution.

Applications and Global Revenue of Custom Check Valves

From industrial processing to medical equipment, a custom check valve can play a crucial role in a variety of industries. In fact, the global check valve market was estimated at around $3.5 billion in 2023, with projections indicating it could grow to nearly $5.2 billion by 2032. Below are some of the most common applications where these specialized valves provide critical functionality.

01

Custom Check Valves in Water and Wastewater Treatment

Essential for preventing backflow and maintaining the efficiency of filtration and pumping systems. With the global water and wastewater treatment market reaching approximately $1.2 billion in 2024 and expected to be $1.8 billion by 2033, check valves continue to be an integral component in ensuring clean and reliable water distribution.

02

Custom Check Valves in the Oil and Gas Industry

Designed to withstand high-pressure environments while offering corrosion resistance. In 2024, the check valve segment within the industrial valve market was valued at $14.8 billion, highlighting its strong demand in oil, gas, and related industries.

03

Medical and Pharmaceutical Custom Check Valves

Critical for controlling the flow of sterile fluids in healthcare applications. The global medical check valves market is valued at approximately $1.67 billion in 2024, with expectations to reach $2.5 billion by 2032.

Request a Quote Today!

Optimize your system’s performance with a custom check valve built to your specifications.

Sources