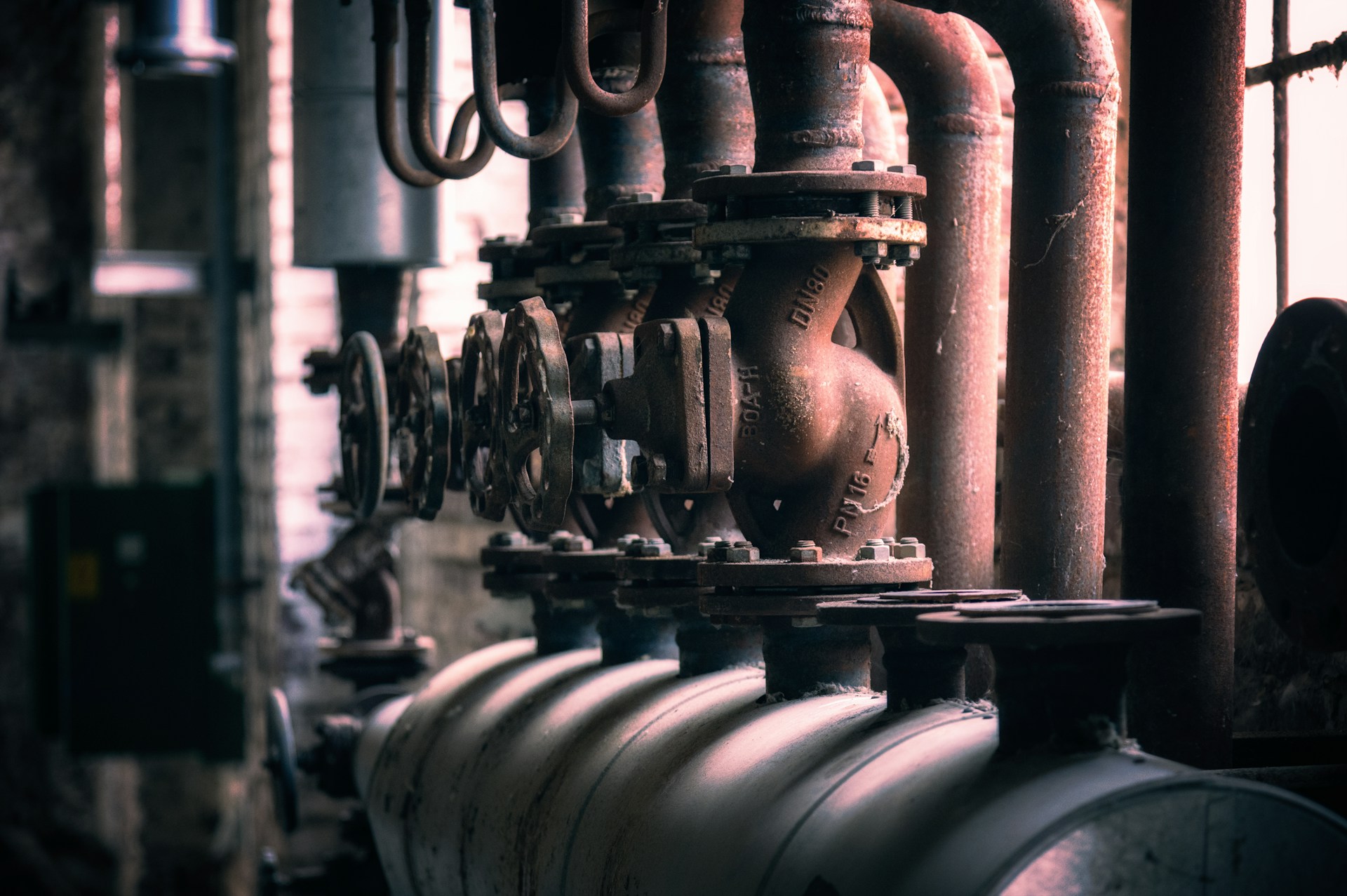

Types of Check Valves

There are several types of check valves, each suited to specific applications and operational requirements. Here are some of the most common types:

- Swing Check Valves: These valves have a disc that swings on a hinge or shaft. When fluid flows in the correct direction, the disc swings open. When the flow reverses, the disc swings back to close the valve.

- Lift Check Valves: These valves use a piston or ball that lifts off the seat to allow flow. When the flow stops or reverses, the piston or ball drops back onto the seat, sealing the valve.

- Ball Check Valves: These valves feature a ball that moves up and down within the valve body. The ball is pushed open by forward flow and seals against a seat when the flow reverses.

- Diaphragm Check Valves: These valves use a flexible diaphragm that opens to allow flow and closes to prevent backflow. They are often used in applications requiring a sanitary or leak-proof seal.

- Wafer Check Valves: These compact valves are designed to fit between flanges. They can be swing or lift type and are used in applications where space is limited.

Applications of Check Valves

These valves are used in a wide range of industries and applications, including:

- Water and Wastewater Systems: To prevent backflow and contamination in pipelines and treatment plants.

- Oil and Gas: In pipelines and drilling operations to ensure the flow of fluids in the correct direction.

- HVAC Systems: To prevent reverse flow in heating, ventilation, and air conditioning systems.

- Fire Protection Systems: To ensure water flows only toward the fire in sprinkler systems.

- Industrial Processes: In chemical processing, power generation, and other industrial systems to maintain the correct flow direction and prevent damage to equipment.

Industries That Use Check Valves

These valves are used in a wide range of industries and applications, including:

- Water and Wastewater Systems: To prevent backflow and contamination in pipelines and treatment plants.

- Oil and Gas: In pipelines and drilling operations to ensure the flow of fluids in the correct direction.

- HVAC Systems: To prevent reverse flow in heating, ventilation, and air conditioning systems.

- Fire Protection Systems: To ensure water flows only toward the fire in sprinkler systems.

- Industrial Processes: In chemical processing, power generation, and other industrial systems to maintain the correct flow direction and prevent damage to equipment.

Benefits of Using Check Valves

The primary benefits include:

- Prevention of Backflow: Protects equipment and processes from reverse flow, which could cause contamination or damage.

- Automatic Operation: No need for external control mechanisms; they operate based on fluid pressure differentials.

- Reliability and Durability: Designed to provide long-term, trouble-free service with minimal maintenance.

- Versatility: Available in various types and materials to suit different applications and operating conditions.

We provide solutions.

Shop our catalog of valves!

Conclusion

Check valves play a critical role in ensuring the smooth and safe operation of fluid systems by allowing flow in one direction and preventing backflow. Understanding the different types of flow and their applications helps in selecting the right valve for specific needs. Whether you’re dealing with water systems, industrial processes, or HVAC systems, check valves are indispensable components that contribute to the efficiency and safety of your operations.

For more information on selecting the right valve for your needs, contact us for support.

Photos by K Adams, Chromatograph, and Peter Herrmann on Unsplash